Hima Engineering Products & Services

It is customary at Hima Engineering Products & Services to give top priority to Customer Service. It is a practice at Hima Engineering Products & Services not only Support the customer on the products sold but also support them on total solution. Hima Engineering Products & Services always strives hard to associate with products that offer utmost performance satisfaction coupled with the service support.This puts Hima Engineering Products & Services high on a Trusted Supplier source.

Product Range

Hima Engineering Products & Services always give priority to Customer First .

Purolator Facet, Inc. is a creative engineering and manufacturing organization offering a wide variety of services and products. Purolator Facet manufactures an assortment of standard filter assemblies qualified to many industry and military standards. High, medium and low pressure filter housings approved to the requirements of MS-28720 and AN6234 meet the filtration requirements of MIL-F-5504, also sections of MIL-F-8815. These filters are just some of the industry standard products available. We also specialize in the design and manufacture of exclusive filter designs for the aerospace industry.

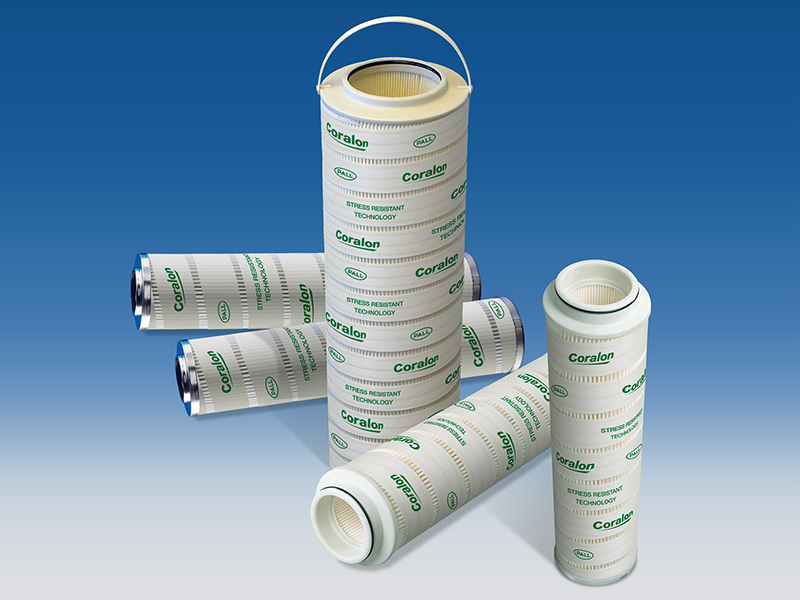

NEW: CoralonTM Filter Elements

Upgrade filter elements for Ultipor®

filters

Keeping fluids cleaner, longer, for greater value

Coralon filters

represent a significant advancement

in equipment protection and are a direct replacement

(same form, fit, and function including fluid and

temperature compatibility) for current Ultipor

filter elements.

Features

Direct replacement for Ultipor elements

• Advanced pack design

• Stress-resistant media technology

• Out-to-in flow path*

* except for in-tank filter options

Innovative Media Performance

Pall’s new

series of hydraulic & lube filter elements feature

SRT (stress-resistant technology) media for unsurpassed

performance and value. Coralon elements provide:

• Low element pressure drop for small envelope size and

long life

• Optimum performance under system stresses at all

stages of filter life for consistently cleaner fluid In addition to improved

performance, what differences will I see?

Coralon filters upgrade Pall Ultipor

III, Ultipor III Coreless, Ultipor Dirt Fuse, Ultipor SRT, Ultipor Plus,

Ultipor Max, and Red1000 elements in all standard

medium grades (Z, P, N, S, T).

• The new elements will have a medium code of “C”

in place of existing “U”, “D”, “K” “M” or “X” code in

the current filter element part number; see examples

in the adjacent table.

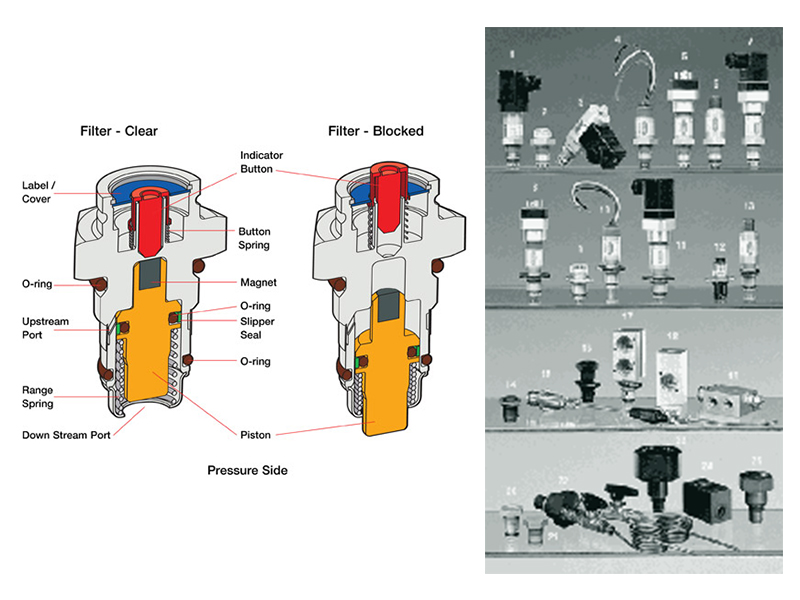

Barton DP indicators, DP switches, IT / ITS / IS Series DP indicating transmitters/switches, and explosion-proof electronic transmitters are available in a variety of safe working pressures and DP ranges for measurement of differential pressure, flowrate, and liquid level applications.

HIGH EFFICIENCY SUPER CLEAN OIL FILTRATION SYSTEMS IS CUSTOM BUILT SYSTEM TO SUIT

CUSTOMER APPLICATION REQUIREMENT

The PALL - High Efficiency Filtration system is a complete system with built-in

pump, motor, filter with all other required accessories. It can be connected to any

of the hydraulic /lube system reservoir as an offline unit and based on the oil

volume it will give NAS Class 3 quality oil (ISO Code 14/11) and better in a short

span of time.

BENEFITS OF HIGH EFFICIENCY PALLSUPER CLEAN OIL FILTRATION SYSTEM

Effective method of removing particulate contamination and maintaining desired

oil cleanliness

level in the hydraulic/lube systems.

Filtration can be

carried out when the system is shut-down.

Filter operation is independent of

main system.

Filtration system can be positioned for easy servicing access.

Hydraulic/Lube system does not have to be interrupted for filter servicing.

Filtration system can be used for filling with system fluid.

To take up the cleaning jobs we need to know about you, Equipment details as given

below and OEM Cleanliness Criteria.

Equipment Details:

Equipment Capacity

Make :

Oil Type in Systems :

Oil grade :

Total Volume of Oil :

Final oil cleanliness level to be

achieved in the oil system reservoir - NAS Class

Water in hydraulic, lubrication, power transmission and insulating fluids adversely affects fluid performance and is a threat to system reliability. Water contamination promotes corrosion and fluid system component wear, resulting in reduced component life and increased maintenance costs. It also degrades fluid properties, leading to reduced lubricity and load carrying ability, oil oxidation and the resultant formation of acids, and additive precipitation. The consequences are reduced fluid service life and increased fluid procurement and disposal costs.The Pall HNP023 Series Oil purifier is designed for use with small to medium oil systems, particularly where high viscosity fluids are employed, and can effectively remove 26 liters of water per day from the oil*. The Pall HNP fluid conditioning purifier uses vacuum dehydration to remove 100 % free water and as much as 90 % of dissolved water. It will also remove 100 % of free and entrained gases and up to 80 % dissolved gases. Vacuum dehydration is the most effective method of water removal at minimum cost and ease of use. Unlike other methods it removes both free and dissolved water and cannot burn or otherwise significantly alter the properties of the oil. Particulate contaminant removal is achieved using high performance rated (ß3(c) >2000) Athalon® filter elements. In addition, a WS12 Series water sensor measures water content and temperature at the purifier inlet, allowing the purifier to operate only when the water content rises above a pre-determined level.

0293 Series Non-Corroding Reservoir Breather Filter

The Pall 0293 disposable air breather is used to prevent damaging

airborne contamination from entering fluid system reservoirs.

Notes and

Specifications

Filtration Rating:

3 micrometers in air

Materials of Construction: Cap and shroud–polyamide

Filtration medium–oleophobic

resin-bonded filter fibers

Method of Construction: Epoxy resin potted

Vacuum Indicator

Minimum Operating

Pressure Setting: 1.1" Hg differential (37 bar)

Vacuum indicator is not a disposable unit. Remove prior

to breather unit disposal.

Temperature range: -4 to + 160°F, (-20°C to +70°C)

Filtration Medium

Collapse Pressure: 15 psid (1 bar) minimum

The Pall 3050 air breather

is used to prevent damaging airborne

contamination entering the fluid system reservoir.

Constructed of corrosion resistant materials, the breather is suitable for

application in wet and humid environments.

If the reservoir can be damaged by vacuum created by a blocked air

breather filter, install a vacuum breaker valve.

To avoid wetting of the filter medium ensure that the clearance between

the bottom of the breather is at least 50mm above the surface of the fluid

in the reservoir.

The Pall PCM500 On-line Fluid Monitor has been developed to provide accurate and

continuous

emailrmation on the cleanliness of aqueous solutions, hydraulic fluids and

circulatory lubrication system

fluids. Fluid contamination levels monitored are then converted to the widely used

contamination

codes: ISO4406, SAE AS4059 table 1 (NAS 1638) and AS4059 table 2. The result data

can be

exported to Flash Drive, Printer, PC, PLC or network device..

The self-contained unit provides a portable fluid contamination monitor that can be

used with a range

of fluids, including mineral oils and aqueous solutions. Fluid change procedures are

included in this

manual and these help ensure the PCM500 monitor is adequately flushed prior to

testing on an

alternative fluid application.

The contents of these operating instructions should be read before attempting any

aspects of

installation, operation or maintenance.

The product has been tested and quality controlled in accordance with Pall standard

procedures. The

customer should carefully inspect the product and ensure it is not damaged and or

unsuitable for use.

It is the user’s responsibility to check actual operating conditions to ensure the

PCM500 monitor is

compatible with the application and is operated within local safety codes.

New: Pall WS19 Series Hand-held

Water Sensor:

The Pall WS19 Series portable water sensor is an

ideal,

low-cost method for measuring dissolved water content in

hydraulic, lubricating and insulating oils.

Specifically designed for use in industrial environments,

readings are shown on an LCD display and can be used

as a key component in the predictive maintenance of plant

and machinery.

Features

• A sensing probe directly immersed in the

fluid to monitor

dissolved water content and temperature

• Water content output in % saturation or PPM

• Temperature in °C or °F

• ‘Plug and play’ connectivity

• Data logging

• Multiple oil constants for PPM conversion

• Simple to operate and calibrate

• Robust housing and sensing probe designs.